|

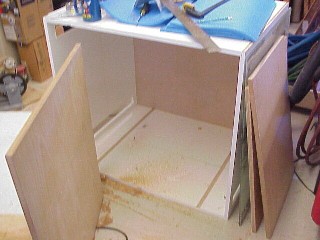

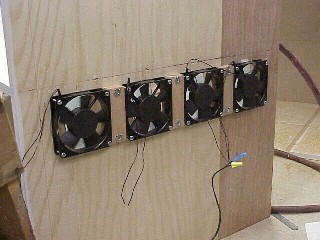

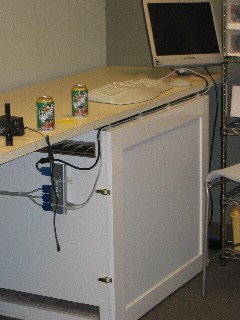

When you are concentrating on a difficult task, there is nothing so disruptive to the process as unexpected changes in background noise. The mechanical design firm for whom this was built occupies what is essentially a one room office. Since they store over a terabyte of data in the form of CAD drawings, they required some fairly serious data storage capability. Additionally, poor quality electrical service mandated a hefty UPS (Uninterruptible Power Supply). But being a firm of 5 or 6 people, they had no space for a sound-proofed data center. The solution was to encase all of their equipment into a sound-proofed cabinet with enough designed-in air flow to keep the equipment cool while keeping the noise level of the office to a quiet level required for the designers to focus on their tasks. As with other commercial projects, pre-finished melamine boards were used for the visible portion of the cabinet work itself, since time spent in woodworking is not cost effective for applications of this nature. This allowed the time to be spent on soundproofing, airflow, and maintenance design considerations. The insulating panels (from www.soundprooffoam.com) are made of recycled fibers, and are more effective for sound-proofing than many foam materials, and are environmentally responsible as well. Because of the complex airflow path, it was necessary to introduce two stages of blowers. The primary inner stage is 4 large 110 VAC powered fans - but noisy. To keep the external noise down, but to provide the additional airflow, an additional two rows of 10 each 60mm fans were added to push air from the inlet to the main fans. These secondary fans required their own 12 VDC power supplies, but more than made up for the trouble by producing very little noise in the finished project while keeping the internal temperature within safe levels. Note that they are also considerably more expensive than the 110 volt fans, but environmental noise is a significant factor in this office. Seen above left is the ducting that allows the airflow load to be handled by a single set of fans. The inlet ducts which split the fan's airflow are on the right. Above right is part of the machining operation for mounting the secondary set of fans in a low-profile setup without having to re-work the original design. Below left is part of the manufacture of the support brackets for the secondary fans. A key part of the design is to make all air flow pass by the soundproofing material (see below right) so that the internal systems are acoustically isolated from the outside. The final product and installation are intended to produce as little impact on the existing environment as possible. Even the inside of the door is lined with soundproofing material. Although difficult to see in the photos, the cabinet door in the lower right photo shows the steel angle-iron used to stiffen the door, and some of the batteries used in the extended UPS (Uninterruptible Power Supply).

|

|

|